Steel sheet and plate are basic materials in a broad variety of sectors, notably in manufacturing, building, and manufacture. The difference in between the 2 largely depends on their density and the applications for which they are matched. Steel sheets commonly vary in density from 1/16 inch to 3/16 inch, while steel plates incorporate thicker products varying from 3/16 inch to a number of inches thick. The flexibility of steel sheets and plates makes them important elements in the production of whatever from structural frameworks and automotive components to shipbuilding and machinery components. Recognizing the properties, kinds, and applications of steel sheets and plates is important for designers, designers, and manufacturers who depend upon these products for their tasks.

One of the most typical forms of steel sheets is hot-rolled steel, which is generated by rolling steel at high temperature levels, making it much easier to form and form. In addition, there are specialized steel sheets, such as galvanized steel, covered with a layer of zinc to supply enhanced corrosion resistance, making it suitable for exterior applications, consisting of roof and exterior siding.

Steel plates come in different grades, consisting of structural, aquatic, and abrasion-resistant, each with specific residential properties tailored for various environments and lots. The selection of the ideal grade and kind of steel sheet or plate is essential for making certain the safety, efficiency, and longevity of the last product.

The manufacturing of steel sheets and plates involves considerable processes consisting of reducing, flexing, welding, and finishing. Welding is another vital procedure in the setting up of steel structures, needing understanding of various welding techniques such as MIG, TIG, and stick welding. The completing procedure might include surface therapies and layers that enhance the material's resistance to rust, boost aesthetics, and extend service life.

The usage of steel sheets and plates has actually developed with advancements in technology, leading to technologies such as high-strength low-alloy steels, which give comparable mechanical homes to standard qualities while minimizing weight. The regular study and growth in the metallurgy of steel are focused on producing lighter, stronger, and much more corrosion-resistant materials, which will further expand the versatility and applications of steel sheets and plates in numerous sectors.

Sustainability is a significantly important consideration in the manufacturing and use steel sheets and plates. Steel recycling has actually been an important part of the market for decades, and most of new steel generated originates from recycled products. This procedure substantially decreases the carbon footprint related to steel manufacturing, helping to address ecological worries. Moreover, producers are taking steps to maximize their procedures, decreasing waste and energy intake, lining up with global sustainability objectives. The capability to produce high-grade steel while lessening environmental influence not only profits the world but additionally improves the online reputation of business committed to lasting practices.

Steel plates serve as vital parts in bridge building, with designers designing steel plate girders to sustain hefty tons and period long distances. In addition, steel sheets are extensively utilized in putting up steel structures, supplying adaptability in style while making certain compliance with structure codes and safety and security requirements.

In the production sector, steel sheets and plates develop the foundation of a significant number of items. From appliances to cars, the need for resilient and trustworthy products is paramount. Automotive producers make use of high-strength steel sheets to produce body panels that are lightweight yet exceptionally sturdy, which adds to enhanced gas performance without sacrificing security. In a similar way, the device industry take advantage of cold-rolled sheets with boosted surface area finishes, guaranteeing visual allure while providing resilient toughness versus everyday wear and tear. The integration of steel sheets in devices and equipment not just boosts the capability of items but also prolongs their lifecycle, get more info supplying significant worth to customers and suppliers alike.

On a more specific note, the oil and gas industry's need for steel plates is driven by the building and construction of pipes and storage space centers that have to sustain severe settings and stress. Steel plates made use of in these applications are usually made to exacting criteria, guaranteeing they can hold up against the roughness of transport and storage space of varied compounds, consisting of unrefined oil and natural gas.

Past commercial applications, the aesthetic utilization of steel sheets has actually discovered a home in architectural layout. The usage of corten steel, understood for its rustic patina, is specifically prominent in creating exterior sculptures and developing facades that mix into natural environments, showcasing the adaptability and charm of steel in numerous style viewpoints.

When it comes to picking providers for steel sheets and plates, several aspects should be taken into consideration to guarantee your projects continue smoothly. The credibility of the distributor, product range, high quality assurance procedures, lead times, and consumer solution are important components in choosing a companion. Lots of fabricators additionally require details accreditations, such as ISO 9001, to make certain that vendors meet global quality monitoring standards. In addition, the accessibility of value-added solutions, such as pre-fabrication and machining, can improve task timelines, offering added value to suppliers and home builders.

As we look towards the future, the role of steel sheets and plates will likely pivot in action to arising technologies and products science. Developments such as 3D printing, which has actually begun to penetrate typical manufacturing worlds, might pave the way to brand-new applications for steel materials and composites. In addition, advancements in wise products that reply to environmental stimuli can bring about the development of self-healing steel or materials with improved efficiency characteristics. The general fad toward modular construction is most likely to more accentuate the significance of steel sheets and plates, as standard parts create effectiveness in setting up and lower on-site construction time.

In verdict, steel sheets and plates are crucial products that create the structure for many applications throughout a diverse variety of industries. As industries strive for innovation and environmental duty, the value of understanding and picking the ideal steel sheets and plates will certainly stay critical to accomplishing functional, cost-effective, and sustainable design remedies.

Val Kilmer Then & Now!

Val Kilmer Then & Now! Barbi Benton Then & Now!

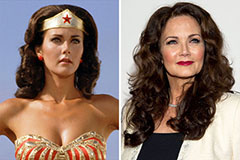

Barbi Benton Then & Now! Lynda Carter Then & Now!

Lynda Carter Then & Now! Rachael Leigh Cook Then & Now!

Rachael Leigh Cook Then & Now! Brooke Shields Then & Now!

Brooke Shields Then & Now!